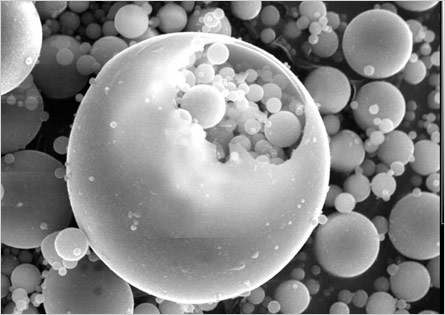

Fly ash is a super fine volcanic ash, grey coloured and amorphous glass powder generated from the gases of burning coal during the production of electricity. These micron-sized earth elements consist primarily of silica, alumina and iron. Almost being spherical in shape, they flow and blend freely in mixtures. That capability is one of the properties making fly ash a desirable admixture for concrete. . They are naturally more thermally insulating than blocks made with other aggregates. As no heat is required, fly ash brick is made by mixing soil, plaster of paris, fly ash and water, it reduces air pollution. The new cement became known as Pozzolanic cement and who was to known that this technology was to have such far-reaching effects on the building and construction industry of today.

The most prestigious projects of recent times have relied on Fly Ash concrete, including high-rise structures, dams, roads, nuclear power stations, bridges and tunnel. Thus, making it eco friendly.

Mineral Admixture in Concrete has two designations for Fly Ash used in concrete - Class F and Class C.

Class F Fly Ash is normally produced from burning anthracite or bituminous coal that meets the applicable requirements. This class of Fly Ash has pozzolanic properties and will have a minimum silica dioxide plus aluminum oxide plus iron oxide of 70%.

Class C Fly Ash is normally produced from sub bituminous coal that meets the applicable requirements. This class of Fly Ash, in addition to having pozzolanic properties, also has some cementitious properties and will have a minimum silica dioxide plus aluminum oxide plus iron oxide content of 50%.

Note:-Specifications and chemical analysis can be furnished only when we get to know the grades/applications desired by you.